Plow solenoid mm2 plows plowsite controler

Table of Contents

Table of Contents

Are you struggling with the wiring of your Boss V Plow Solenoid? Do you want to know how to properly wire it to ensure its proper functioning? If yes, then you’ve come to the right place. In this blog post, we will walk you through everything you need to know about Boss V Plow Solenoid Wiring Diagram and related keywords. From the basics to the technicalities, we’ve got you covered. So, let’s dive in!

Pain Points

When it comes to wiring a Boss V Plow Solenoid, there are a lot of factors that can cause problems. There are several wires involved, and if they are not connected correctly, it can lead to malfunction, less or no power supply, and other issues. One of the most significant factors that cause difficulties is the lack of proper knowledge, skill, and experience in wiring the plow solenoid. With insufficient information, it can be very frustrating and time-consuming just to understand what to do, let alone fix it.

Target of Boss V Plow Solenoid Wiring Diagram

The Boss V Plow Solenoid Wiring Diagram is designed to help you understand the wiring situation of your plow solenoid. It provides a clear picture of the wiring layout, including the correct wiring colors and their functions. With this diagram, you can identify the key components for a successful wiring job and ensure that everything is correctly connected. It is an essential tool to prevent any complications and minimize frustration when dealing with your plow solenoid.

Main Points Summarized

In summary, Boss V Plow Solenoid Wiring Diagram is a vital tool to help you wire your plow solenoid correctly. It is designed to show you everything you need to connect and how to do it accurately. With the diagram, you can identify the key components in wiring your plow solenoid and increase your grasp of the wiring layout.

Boss V Plow Solenoid Wiring Diagram - How it Works

When wiring your Boss V Plow Solenoid, the first thing to do is to understand the wiring diagram. The wiring diagram provides a visual representation of your plow solenoid’s wiring configuration, enabling you to identify the wires correctly. It also provides information on which wire deserves connectivity, making the application more straightforward. A top tip is to label all the wires by the letter indicated in the diagram to avoid confusion. A critical step in this process is to use the correct tools and techniques to prevent mistakes and ensure optimal performance.

Importance of Proper Wiring

Importance of Proper Wiring

Proper wiring of your Boss V Plow Solenoid is essential to ensure that your plow functions correctly, especially in winter months where it can have its busiest season. With proper wiring, you reduce the risks of power failure or damage to your plow solenoid, enabling it to retain its functionality throughout. Correct wiring also extends the life of your Boss V Plow Solenoid by limiting the likelihood of malfunctions, degradation in performance, and breakdowns.

### Proper Wiring Tips

### Proper Wiring Tips

When wiring your Boss V Plow Solenoid, it is essential to follow some strict guidelines to ensure its proper functioning. These include using high-quality wires, using the correct tools, connectors, and crimpers. It is also essential to label all the wires clearly by letters indicated in the diagram and connect them as illustrated in the wiring diagram. It’s important to avoid bending the wire and ensure that all connections are well-protected from the elements.

Additional Wiring Tips

Other things to consider when wiring your Boss V Plow Solenoid include proper grounding, secure connections, and good wire management techniques. Proper grounding helps dissipate any static electricity and reduces the possibility of electrical shocks. Secure connections are important to avoid any risk of short circuits, and good wire management techniques help you to keep the wires neat, organized, and secured to the plow’s structure, avoiding damages from external factors.

Question and Answer

Q: Can you use any wire for Boss V Plow Solenoid Wiring?

A: No, you cannot use any wire for Boss V Plow Solenoid Wiring. You need to use specific high-quality wires to ensure the proper functioning of your plow solenoid.

Q: Why is labeling the wires important in Boss V Plow Solenoid Wiring?

A: Labeling your wires is important in Boss V Plow Solenoid Wiring to avoid confusion, reduce chances of mistakes and save time. It helps you to find the right wire that needs connection, avoiding any risks of connecting the wrong wire.

Q: What are some tips for maintaining the wiring on my Boss V Plow Solenoid?

A: Some tips for maintaining the wiring on your Boss V Plow Solenoid include checking regularly for any damaged wires, properly securing the wires, and ensuring that they are adequately protected from the elements.

Q: How often do I need to replace the wires on my Boss V Plow Solenoid?

A: The frequency of wire replacement depends on a variety of factors, such as the quality of the wire, frequency of usage, and the conditions in which it is used. Generally, high-quality wires can last up to 4-5 years, while lower-quality wires typically last 2-3 years.

Conclusion of Boss V Plow Solenoid Wiring Diagram

In conclusion, proper wiring of your Boss V Plow Solenoid is essential to ensure its proper functioning, prevent damages and extend its lifespan. Boss V Plow Solenoid Wiring Diagram is a useful tool that provides a clear picture of the plow solenoid wiring configuration, helping you navigate the maze of wires correctly. Remember to follow the proper wiring tips, apply the best practices, label your wires, and use high-quality wires and connectors to minimize mistakes and ensure optimal performance.

Gallery

Boss Plow Wiring Diagram Chevy - 36guide-ikusei.net

Photo Credit by: bing.com / plow boss wiring diagram chevy 2021

Boss V Plow Wiring Diagram - Free Wiring Diagram

Photo Credit by: bing.com / wiring plow boss diagram snow western light schematic plows solenoid wire controller pro meyers sno arctic rt3 headlights meyer md2

Boss V Plow Wiring Diagram – Easy Wiring

Photo Credit by: bing.com /

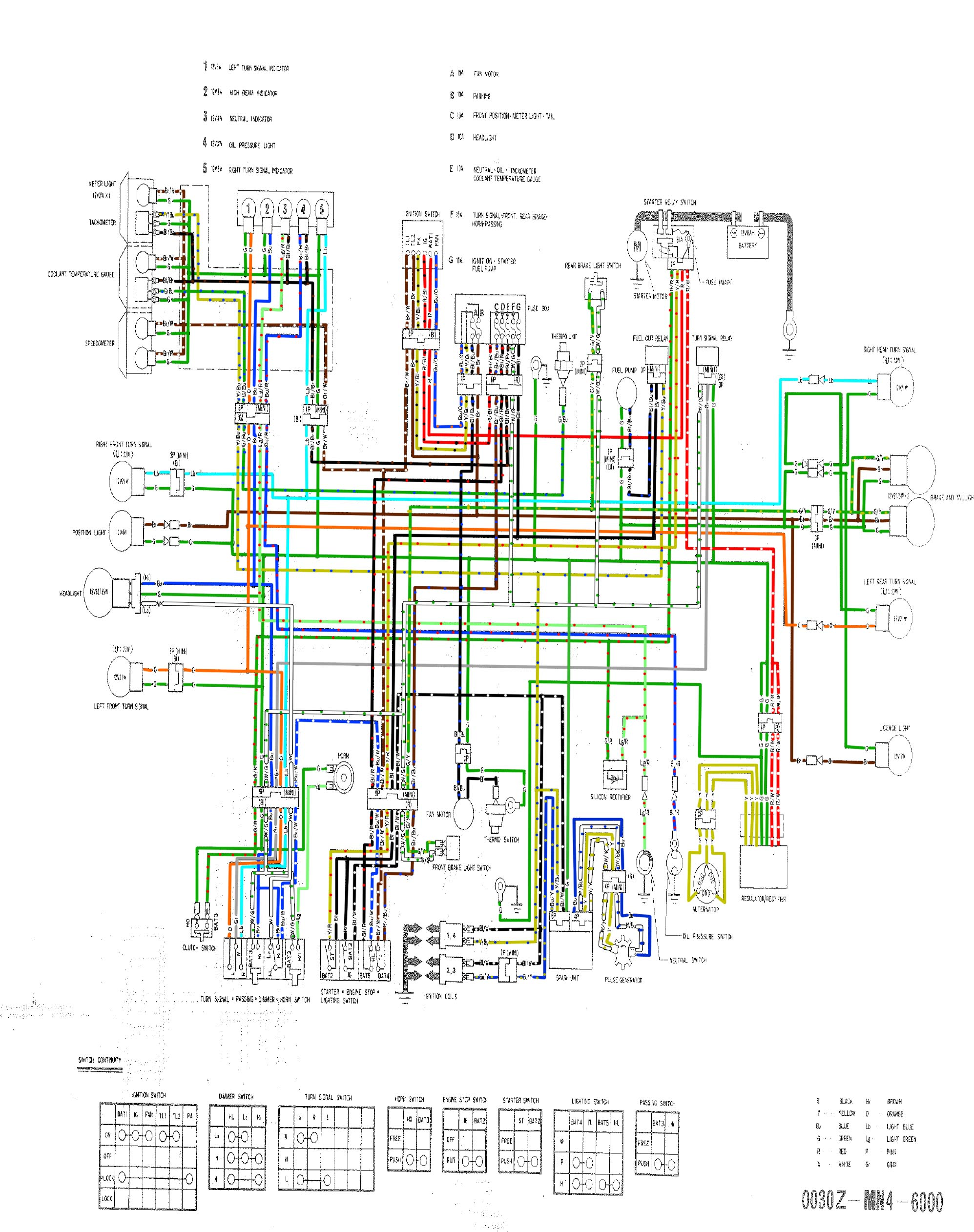

Fisher Plow Solenoid Wiring Diagram - General Wiring Diagram

Photo Credit by: bing.com / plow solenoid mm2 plows plowsite controler

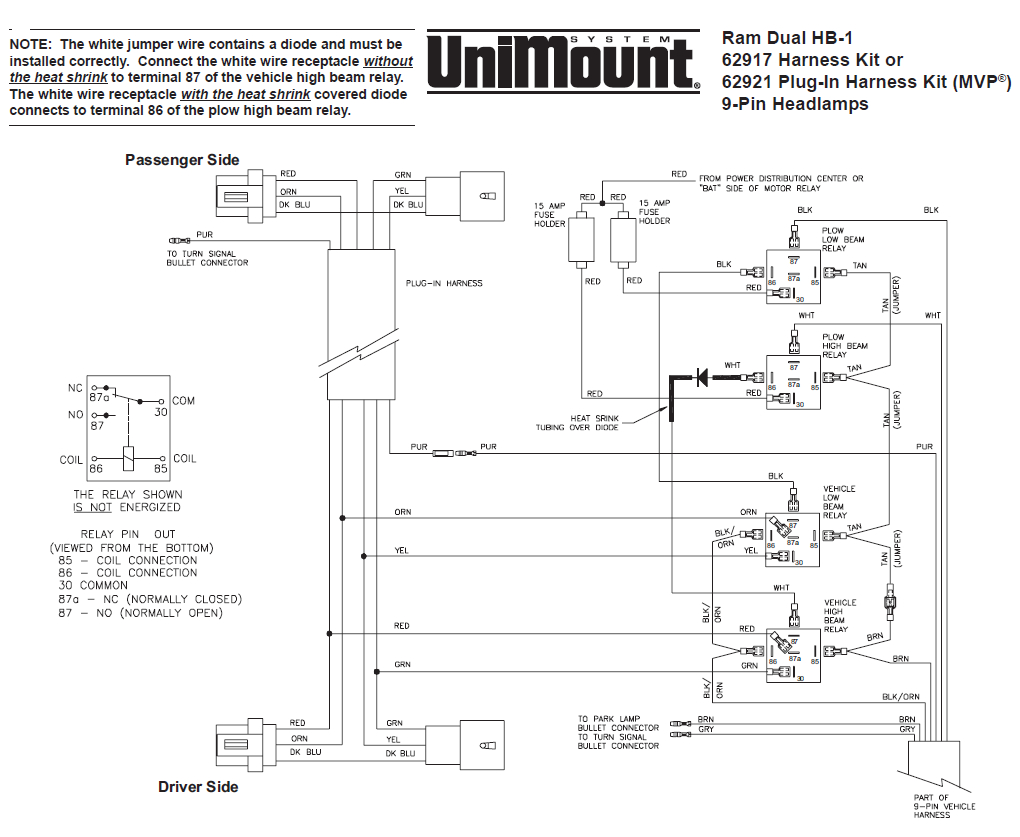

Western Snow Plow Solenoid Wiring

Photo Credit by: bing.com / plow solenoid unimount monarch hydraulic plowsite joystick plowing diagramweb

Boss Plow Solenoid Wiring

Photo Credit by: bing.com /

Boss Snow Plow Solenoid Wiring Diagram - Wiring Diagram Schematic

Photo Credit by: bing.com /

Boss Plow Wiring Schematic | Free Wiring Diagram

Photo Credit by: bing.com / wiring plow diagram boss snow meyer light schematic western plows switch wire snowdogg electrical diagrams lights painless blade straight meyers

Boss V Plow Wiring Diagram - Wiring Site Resource

Photo Credit by: bing.com / boss diagram wiring rt3 plow parts wing snow functioning controller ford plowsite bos

Boss Plow Wiring Diagram - Cadician’s Blog

Photo Credit by: bing.com / wiring plow diagram western snow unimount harness dodge solenoid boss headlight ram kit hb spreader lights controller salt wire snowplow